Since there are many different types of applications for pressure sensors, there are many types of sensors available with a wide variety of characteristics, whether it’s for harsh or corrosive environments, medical equipment or mobile devices. Selecting a pressure sensor means choosing from a vast array of technologies, packages, performance levels and features in order to meet multiple demands for accurate pressure measurement, such as:

· Gas pressure inside a tank, such as an industrial-compressor reservoir

· Measuring level or volume of liquid contained by sensing the pressure at the bottom of a vessel

· Measuring pressure differences between two points in a system, as a means of monitoring or quantifying the flow of liquids or gases

· Barometric pressure: change in atmospheric pressure with weather conditions or with altitude. Useful in weather stations, environmental monitoring, or to assist navigation dead reckoning alongside GPS or cell triangulation

What is pressure?

Pressure = Force / Area

In SI (MKS) units, a force of one Newton, applied to an area of one square meter, exerts a pressure of one Newton per square meter, or one Pascal.

Any kind of pressure sensor contains a mechanism or structure that reacts proportionately to a force applied. The area over which the force is applied is constant, for a given sensor structure.

There are three different types of pressures that can be measured: gauge, absolute, and differential.

Gauge pressure, Absolute pressure or Differential pressure?

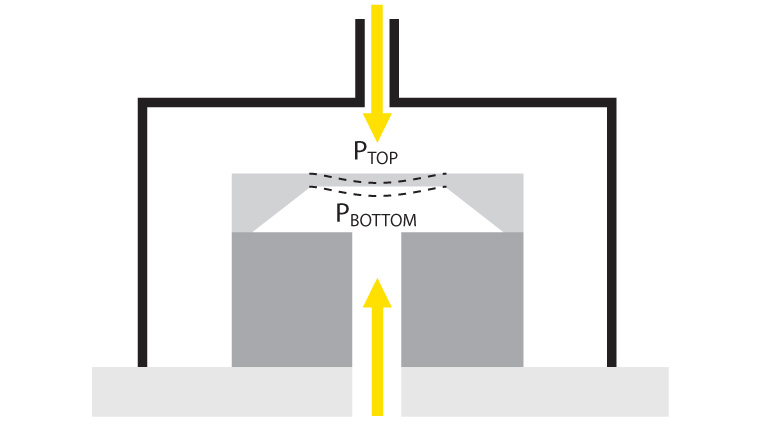

Gauge pressure

Gauge pressure is the pressure measured relative to the ambient atmospheric pressure. It can be positive for pressures higher than atmospheric, or negative for lower pressures. A gauge pressure sensor will have two ports, allowing the media at the reference pressure, and at the pressure. A typical application for a gauge pressure sensor is to measure water oil liquid levels gas pressure in a vented tank using the difference in hydrostatic pressure and ambient atmospheric pressure. Most pressure transmitters on the market measure gauge pressure, because the majority of industrial applications can use gauge pressure.

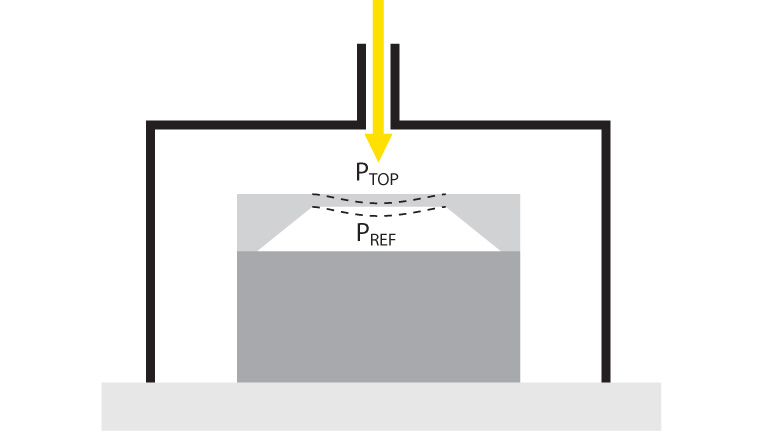

Absolute pressure

Absolute pressure sensors will give the result relative to zero (a perfect vacuum). Sensors will have one port for the media to enter and exert pressure on the sensing element, producing a positive change in output, of magnitude proportional to the pressure applied.

This is useful in applications that are measuring atmospheric pressure, perhaps to determine altitude. Absolute pressure sensors are also used in pressure measurement applications that will be used at different altitudes, since atmospheric pressure varies with altitude, gauge pressure wouldn’t give an accurate reading. This type of sensor is used in tyre pressure monitoring systems to optimise tyre performance.

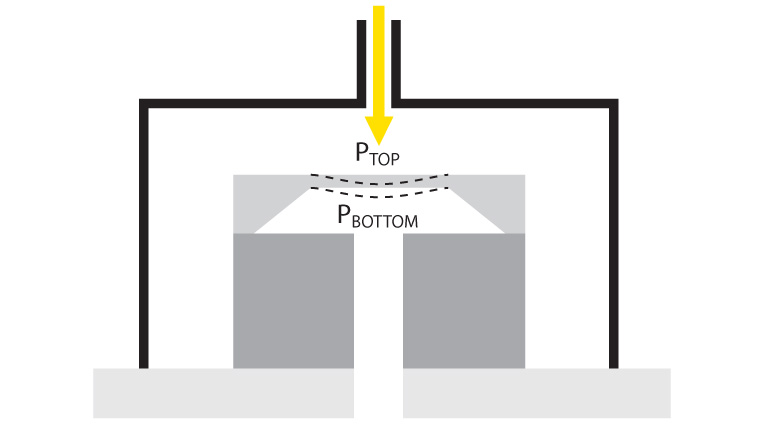

Differential pressure

Differential pressure sensors measure the difference in pressure between two points, similar to how a gauge sensor works. But in this case the reference pressure is one of the points in the system, as determined by the system designer. The change in differential output is positive or negative, depending on which is greater. The magnitude of the change is proportional to the pressure difference between the two domains.

As an example, differential sensors are sometimes used to detect the pressure difference either side of an object. Differential pressure sensors are often used to monitor airflow in HVAC applications,like clean room, vanitation pipe, indoor air pressure monitoring, air filter monitoring…

Pressure sensor, transducer, or transmitter?

It is worth noting that “pressure sensor” is a generic term to describe a pressure-sensing device that may be a sensors, a transducer or a transmitter, depending on the design of associated electrical circuitry.

The sensing element responsible for detecting and quantifying the effects of applied pressure produces an output that cannot be used directly in an electronic circuit – like a microcontroller-based system. The physical response needs to be translated into an electrical signal, and then signal conditioning is required to create a suitable, usable signal.

Pressure sensors

Pressure sensors produce an output voltage that varies with the pressure it experiences, usually referring to the sensor element that is physically detecting the pressure. Packaged board-mount pressure sensors are available which will require the designer to consider calibration, temperature compensation and amplification separately.

Confusingly, the phrase “pressure sensor” is also sometimes used to describe transducers and transmitters in general. Our engineers regard the sensor more as a chip core, and we use more oil-filled silicon (diffusion silicon) cores instead of ceramic cores, which have better measurement range and accuracy.

Pressure transducers

Pressure transducers, like pressure sensors, produce an output voltage that varies with pressure. A transducer in this context is a sensing element combined with signal conditioning circuitry, perhaps to compensate for temperature fluctuations, and most likely an amplifier to allow transmission of signals further from the source. Note that for most applications there is an advantage to specifying pressure transducers that are temperature compensated rather than trying to implement custom temperature compensation on a pressure sensing element, as the testing required can be complicated and difficult.

Pressure transmitters

Pressure transmitters are similar to transducers, but generate a current signal across a low-impedance load rather than a voltage signal. Typically the output will be a 4-20mA standard industrial output. But now the market is not very concerned about the confusion of the names of the three, and there are current, voltage and resistance outputs. Be aware that in portable applications, transmitters can wear the batteries down if they are consistently used at the top end of their pressure range.

Working principle of a pressure sensor

An electronic pressure sensor relies on a physical reaction to applied pressure, and then measuring the resulting proportional change electronically. Commonly used phenomena include changes in capacitance, or changes in ohmic resistance of a strain gauge or piezoelectric element, which are proportional to the magnitude of the deflection when pressure is applied.

Important criteria such as measurement range, environmental suitability, physical size, and power requirements, and the type of pressure measurement required will have a significant guiding influence on engineers looking for an application specific solution.

Capacitive pressure sensors

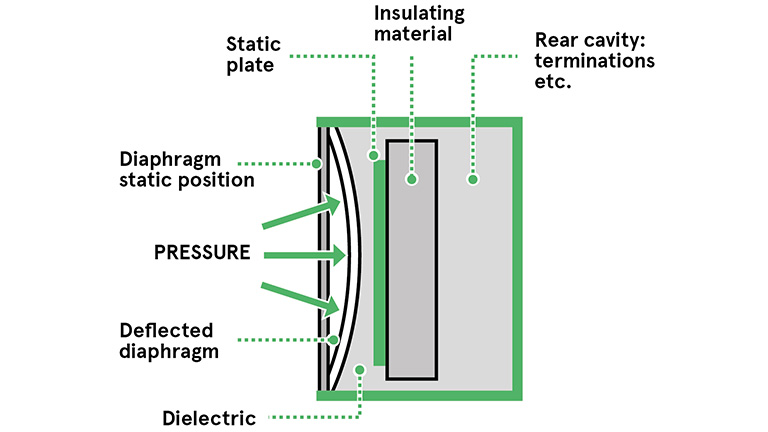

A capacitive pressure sensor contains a capacitor with one rigid plate and one flexible membrane as electrodes. The area of these electrodes being fixed, the capacitance is proportional to the distance between the electrodes. The pressure to be measured is applied to the flexible-membrane side, and the resulting deflection causes a change in capacitance that can be measured using an electrical circuit.

A capacitive pressure transducer relies on capacitance change produced by deflection of the membrane, which alters the capacitor geometry

Strain-gauge pressure sensors

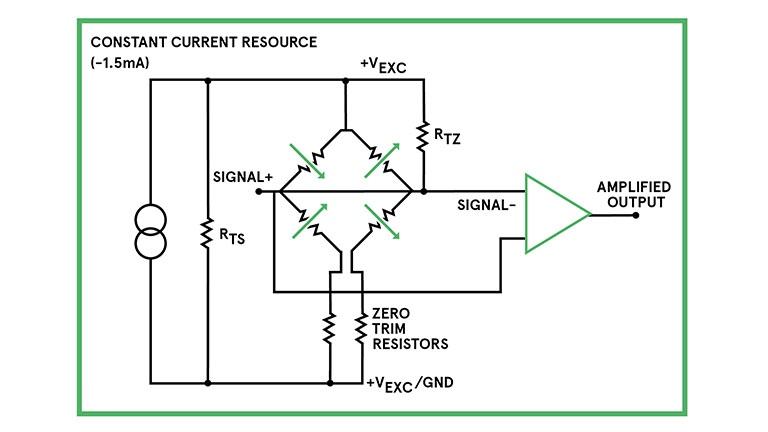

In a strain-gauge type pressure sensor, foil or silicon strain gauges are arranged as a Wheatstone bridge. The strain gauge is attached to some kind of diaphragm, which deflects when pressure is applied. The resulting signal is then measured, amplified and conditioned by the Wheatstone bridge circuit to provide a suitable transducer-voltage or transmitter-current output representative of the applied pressure, as shown in the diagram.

A circuit diagram of a bridge type sensor

Piezoresistive pressure sensors

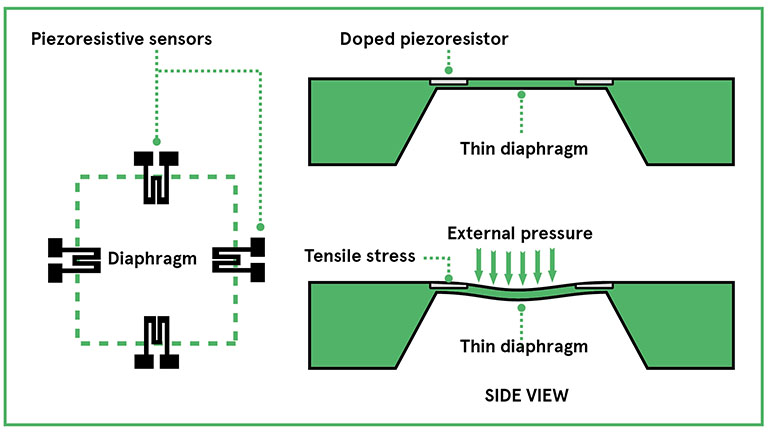

Piezoresistive sensing elements can also be arranged in a similar bridge formation. The diagram below illustrates how the sensing elements of a bridge-type pressure sensor are attached to a flexible diaphragm, so that resistance changes according to the magnitude of the diaphragm deflection. The overall linearity of the sensor is dependent on the stability of the diaphragm, over the stated measurement range, as well as the linearity of the strain gauges or piezoresistive elements.

Piezoresistive pressure sensor elements measure resistance changes according to the magnitude of diaphragm reflection

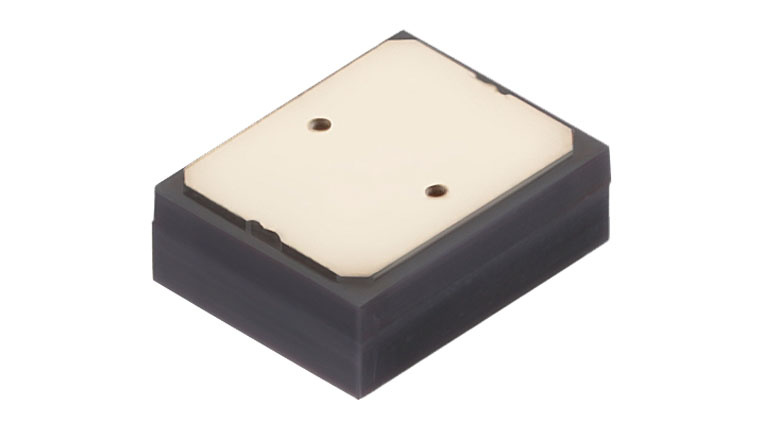

MEMS sensors

It’s easy to imagine a piezoresistive or capacitive pressure sensor as a large device ,and MEMS is the mini type. Unfortunately, LEFOO currently has no plans to develop MEMS products.

Design considerations

Understanding the types of sensors in common use, their operating principles, and modes of use (absolute, gauge, or differential) can help engineers make initial selection decisions when identifying the most suitable sensor to choose for a given application.

The materials used and type of construction can have an important influence over aspects such as the measurement range, limiting factors like the maximum survivable pressure to which a sensor can be exposed, its stabilising time after soldering, and long-term stability in the intended application.

An understanding of the electrical output properties, and the circuitry needed to interact properly with the host electronic system – typically a microcontroller- or microprocessor-based control system — can help assess how the choice of pressure sensor will influence the likely electronic integration challenges.

.jpg)